Security Cameras Get Smart: AI-Powered Monitoring for Industrial Safety & Efficiency

CCTV cameras are a common part of the industry nowadays. In the Industry 5.0 stage artificial Intelligence, particularly Computer Vision, sets these devices apart as a groundbreaking innovation in Manufacturing. AI Smart cameras do more than simply observe and monitor; they actively contribute to Industrial safety by enabling proactive measures across various industries. From detecting Industrial Safety violations to Total productive maintenance, let’s understand how security cameras are making a difference.

But that's not all. –

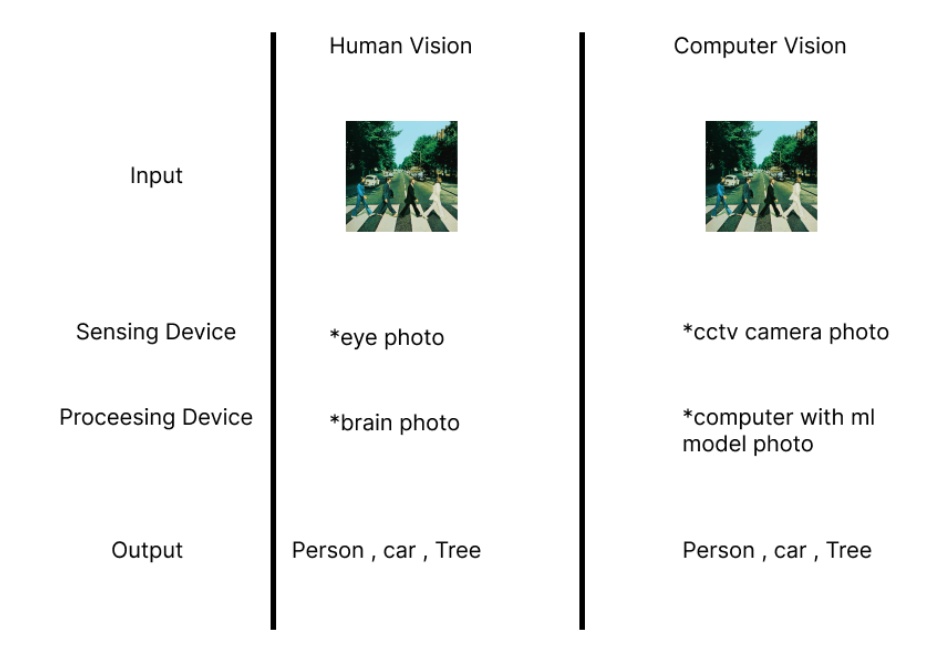

Using computer vision we can convert normal CCTV cameras into AI Smart cameras. An AI Smart camera is a standard CCTV camera enhanced with computer vision technology. Computer vision, a subset of artificial intelligence, aims to emulate human perception, cognition, and decision-making by using the latest technologies by processing every frame. Nowadays without human intervention, computer vision understands our world better.

How are AI-smart security cameras utilized in industrial places?

AI Smart cameras can be used in various industries to achieve multiple objectives. For example, an AI Smart camera can be used for Real-time Monitoring of PPE, Hazardous Area Monitoring, and Product production count monitoring. Let's look at some examples to understand the various applications of AI Smart cameras.

Hot Dip Galvanizing Factory

While galvanizing seems straightforward – dipping metal beams in molten zinc – the reality is a complex dance between people and machines. Even minor missteps can jeopardize Industrial safety, quality, and ultimately, production output.

One of the biggest bottlenecks to productivity is the lack of a comprehensive monitoring system. Manual tracking methods struggle to capture the full picture, leading to several key challenges:

- Blind Spots - It's nearly impossible to manually track everything – human errors, machine downtime, material availability, and adherence to process steps all go partially unrecorded.

- Data Inaccuracy - Manual records are prone to errors, making it difficult to rely on the data for clear insights.

- Limited Visibility - Without a holistic view of the entire operation, it's challenging to identify areas for improvement and optimize production flow

Manual tracking methods hold galvanizing productivity hostage. By implementing AI Smart cameras, plants can eliminate blind spots, ensure data accuracy, and gain a holistic view of operations, paving the way for significant productivity gains.

Industrial Safety Compliance in Manufacturing

Traditional safety methods often have blind spots. Manual monitoring can be tedious and prone to error while relying solely on worker awareness has limitations. This can lead to safety violations, accidents, and ultimately, production slowdowns.

By integrating AI with computer vision systems, manufacturers can achieve a new level of safety oversight. Cameras with AI smarts can continuously monitor activity, identify unsafe situations, and trigger real-time alerts. This empowers companies to:

- Automate PPE Compliance - Continuously verify the proper use of personal protective equipment, reducing human error and the risk of accidents.

- Predict Equipment Failure - Detect anomalies in machine operation, enabling proactivemaintenance and preventing breakdowns that could injure workers.

- Secure Hazardous Areas - Grant or deny access based on real-time safety compliance, keeping unauthorized personnel out of harm's way. Incorporating AI and computer vision creates a proactive safety culture, minimizing risks and maximizing productivity.

Truck analytics and Weighbridge monitoring

Traditional truck arrival and data recording at weighbridges are often manual andtime-consuming. This can lead to delays, inaccuracies, and security concerns.

- Automated Truck Arrival Detection - The system automatically detects truck arrivals at the weighbridge, eliminating the need for manual signaling.

- ANPR (Automatic Number Plate Recognition) - AI accurately reads license plates,streamlining data entry and reducing human error.

- Driver and Personnel Presence Detection - The system can detect the presence of drivers and other personnel on the weighbridge, enhancing Industrial safety measures

Automating tasks significantly reduces processing times, leading to faster truck turnaround times. Eliminating manual data entry minimizes errors and ensures data integrity. Automated processes reduce unauthorized access and manipulation of weighbridge data. The system provides real-time data on truck arrivals, and personnel presence, enabling better decision-making. Improved efficiency and reduced errors lead to overall cost savings in weighbridge operations.

Benefits of AI Smart cameras:

Traditional security cameras offer a passive view, but AI takes things a step further. Here's how AI Smart cameras boost your security game:

- Smarter Surveillance - AI analyzes footage, distinguishing real threats from false alarms.This allows for quicker response times to actual security breaches

- Always on Guard - Unlike human guards, AI never sleeps. You get 24/7 vigilance without interruptions, for complete peace of mind.

- Finding What Matters - Forget sifting through hours of footage. AI categorizes video,letting you instantly find relevant clips for investigation.

- Cost-Conscious Security - AI automates tasks, reducing reliance on manpower. This translates to a more cost-effective approach to security

- Future-Proofed Protection - As threats evolve, so can AI. These cameras can becontinuously updated to recognize new security risks

With these advantages, AI Smart cameras are becoming an essential tool for modern security and business operations.