Why 4M Monitoring Is Becoming the Backbone of Modern Production Lines

The heart of any factory is its production line - and its biggest enemy is inconsistency.

Picture a late shift on a busy shopfloor. A press runs a little hotter than usual. A new operator skips a tiny step. A raw-material batch looks fine but isn’t quite right. Nothing fails loudly. No alarms scream. Yet quality quietly slips and losses start to stack up.

These small, unnoticed changes create production line deviations that lead to defects, rework, wasted material, and that exhausting cycle of daily firefighting. This is exactly why manufacturers are turning to real-time visual intelligence platforms like SeeWise’s Industrial Computer Vision solutions to detect early signs of deviation and act before quality is affected.

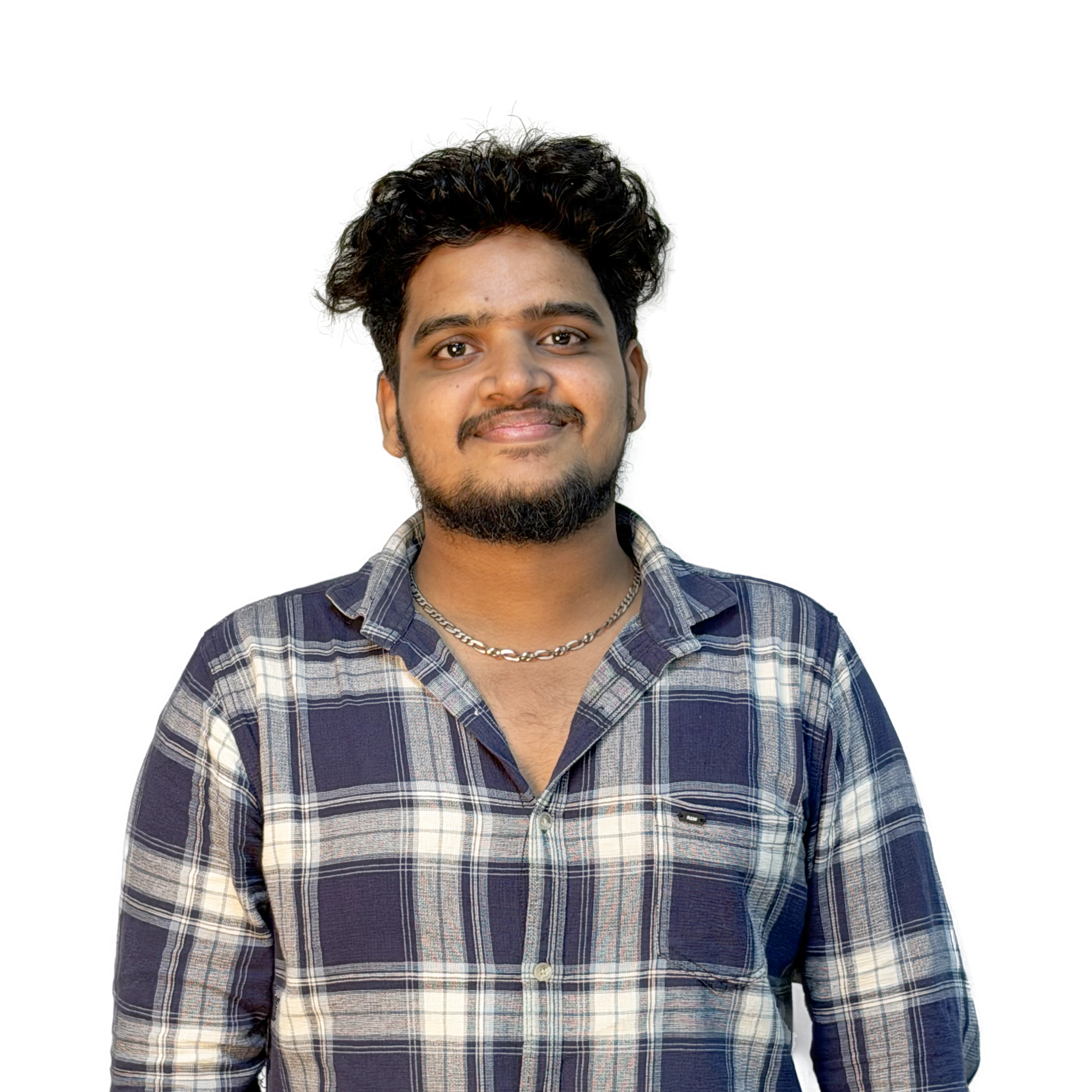

For decades, manufacturers have relied on the 4Ms - Man, Machine, Material, and Method - to diagnose problems after they occurred. Teams used the framework to explain yesterday’s defect, often following traditional 4M analysis practices. Today, the shift toward a proactive 4M monitoring system means factories don’t just analyze defects - they prevent them. Many teams begin by discussing their shopfloor challenges directly to understand where process drift is entering their operations.

Today, that’s changing.

The digital shift in 4M in manufacturing has transformed the framework into a proactive 4M monitoring system. Instead of waiting for evidence of failure, factories now detect operational instability early and act before quality is affected. With sensors, IoT, and AI, teams gain real shopfloor variation control, using smart factory solutions from SeeWise to stabilize operations in real time.

The 4Ms on a Real Shopfloor

Every “M” now works as a live safeguard - not a post-mortem checklist.

Man, and Method

On the line, a camera doesn’t just watch - it verifies. Vision systems confirm safety gear is worn and each assembly step follows the defined process. When a task is skipped or a part is misaligned, the issue is flagged immediately. What once depended on occasional supervision now runs on continuous proof. SeeWise’s shopfloor monitoring modules make this possible.

Machine

A machine rarely fails all at once. It whispers first - through heat, vibration, or small performance shifts. Sensor data captures these early signals. Maintenance teams receive alerts before parts wear out, allowing fixes to be scheduled during planned downtime instead of reacting to sudden breakdowns.

Material

Quality problems often enter long before production starts. Automated checks validate temperature, surface condition, or consistency at line speed. Poor inputs are stopped at the gate instead of moving downstream and turning into scrap. Together, these controls turn the traditional 4M concept into a living system that sees, records, and reacts to operational changes as they happen.

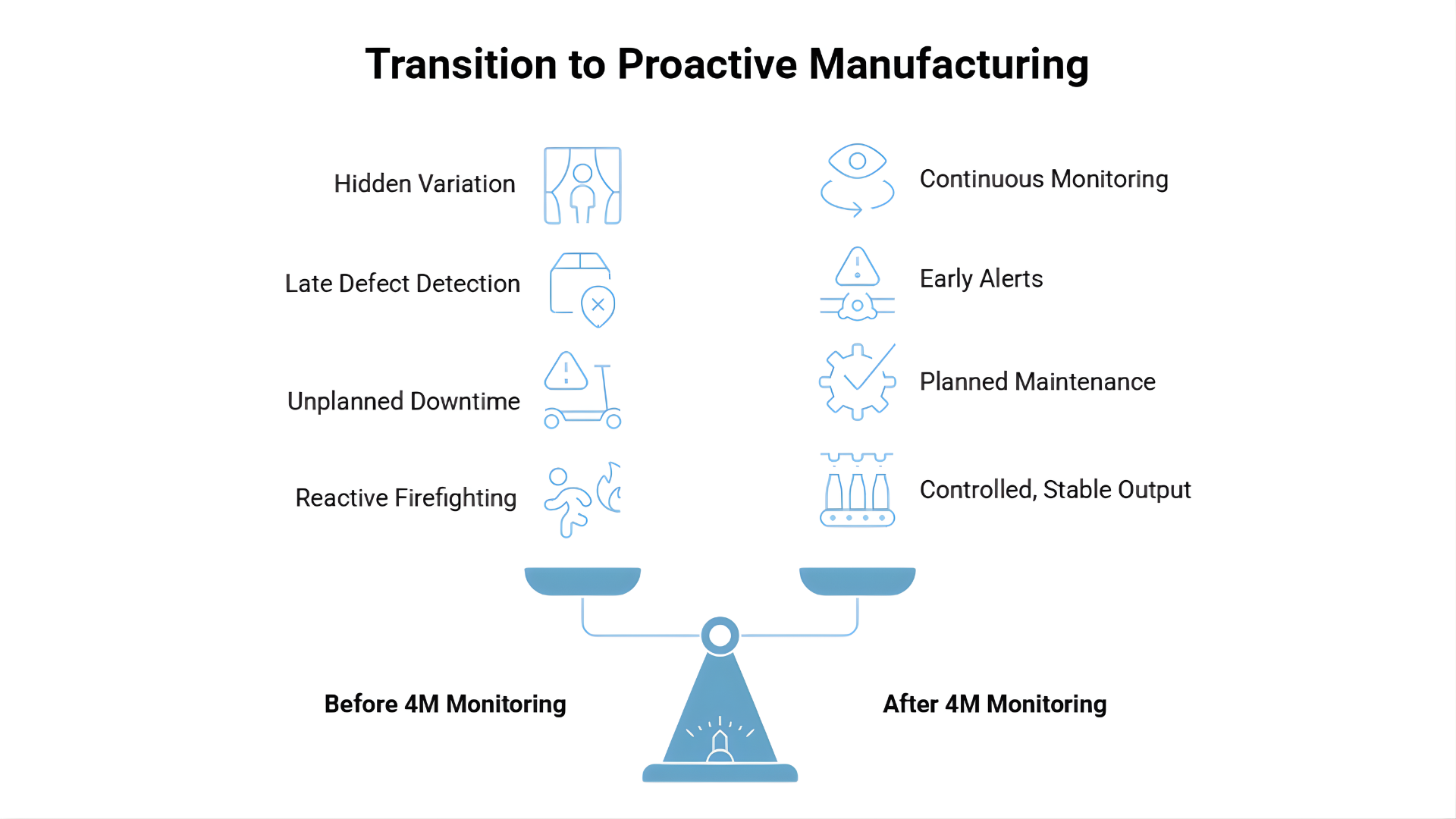

Turning Chaos into Control

The real power of a digital 4M monitoring system lies in its ability to make the unpredictable predictable. When process drift goes unseen, it drains time and money. When it’s detected early, it becomes manageable. Every deviation leaves a digital trail. Patterns that were once guessed are now visible. Issues that used to surprise teams become familiar and preventable. This shift defines modern manufacturing. Instead of chasing defects at the end of the line, teams stop them mid-process. Instead of debating root causes, they review visual proof. Instead of downtime “just happening,” maintenance becomes planned, precise, and quietly efficient.

Why the Future Runs on 4M Monitoring

Competition is relentless. Margins are thin. Customers expect consistency every time. That’s why modern factories depend on a digital 4M framework to deliver stable production, fewer defects, planned maintenance, and faster decisions driven by real data. Continuous improvement is no longer manual or reactive - it scales naturally when quality fluctuations are controlled at the source. With Vision AI in manufacturing, factories don’t just track quality. They actively control it.

Why 4M Monitoring Is No Longer Optional

4M monitoring is no longer a theory - it’s operational infrastructure. As production lines become faster and more complex, manufacturers that detect instability early will lead. Those who don’t will continue fixing yesterday’s mistakes. The factories that win tomorrow are the ones that see today clearly and act before problems ever surface.