Corrective Action & Root Cause – Why SeeWise Now Solves the Why, Not Just the What

SeeWise Now Solves the Why, Not Just the What

We are thrilled to announce a game-changing update to SeeWise, our Safety AI platform designed to take your workplace safety to the next level.

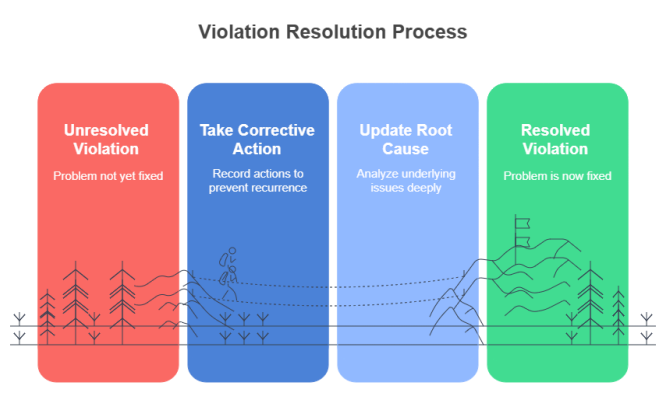

With our latest feature rollout, you don’t just detect safety violations—you understand them.

The new module enables in-depth Root Cause Analysis and Corrective Action Planning, ensuring that once a problem is spotted, it’s addressed for good.

Why Does This Matter More Than Ever?

In high-risk industries like manufacturing, warehousing, logistics, and construction, safety isn't optional—it's mission-critical.

Accidents stem from overlooked causes, repeated mistakes, and lack of follow-through.

That's why we're on a mission to eliminate repeat incidents and help companies like yours move toward zero fatal accidents.

What’s New in SeeWise

With this powerful new update, SeeWise helps you:

- Identify the Root Cause – Get crystal-clear insight into what actually led to the unsafe event.

- Implement Corrective Action – Take meaningful, targeted steps to eliminate the cause and ensure compliance going forward.

Real-World Safety Violations: PPE Non-Compliance Examples

To help you understand how impactful this new feature can be, here are a few real-world PPE (Personal Protective Equipment) violation scenarios that SeeWise can now analyze more deeply:

1. Missing Hard Hat in a Construction Zone

Violation Detected: A worker is operating near a crane without wearing a hard hat.

Root Cause: Inadequate supervision and unclear PPE signage near entry points.

Corrective Action: Update signage, conduct refresher safety training, and assign a PPE check supervisor for each shift.

2. No Safety Glasses in a Manufacturing Line

Violation Detected: Operator at a grinding machine seen without protective eyewear.

Root Cause: Safety glasses station was empty; inventory not tracked.

Corrective Action: Implement PPE inventory alert system and assign PPE restocking responsibility.

3. Mask Non-Compliance in Chemical Handling Zone

Violation Detected: Worker handling volatile chemicals without a respirator.

Root Cause: Respirators were stored in an inaccessible cabinet.

Corrective Action: Redesign PPE storage for quick access and train staff on zone-specific PPE requirements.

How This Helps Your Business

- Prevent Repeat Offenses – You're not just treating the symptoms, you’re fixing the system.

- Simplify EHS Audits – Track violations, actions taken, and outcomes with full traceability, making your audits smoother and more transparent.

- Reduce Incident Rates – Fewer violations mean fewer injuries and production stoppages.

- Build a Safety-First Reputation – Employees feel safer, morale improves, and your brand earns trust from stakeholders and clients.

SeeWise = Safer Workplaces

With this new feature, your team can move from “What went wrong?” to “How do we make sure this never happens again?” in just a few clicks.

Whether it's a PPE violation, improper machine use, or a near-miss, SeeWise doesn’t just alert you—it empowers you to act.

Ready to revolutionize your safety protocols and achieve tangible results?

Join leading manufacturers who are already experiencing significant improvements, with some reporting a reduction in incident rates by as much as 43% by partnering with SeeWise. SeeWise acts as your dedicated AI EHS partner, autonomously detecting violations, diagnosing root causes, and directing immediate responses.

Schedule a live demo today to see how our innovative platform can transform your workplace safety. Visit us to learn more:SeeWise.AI